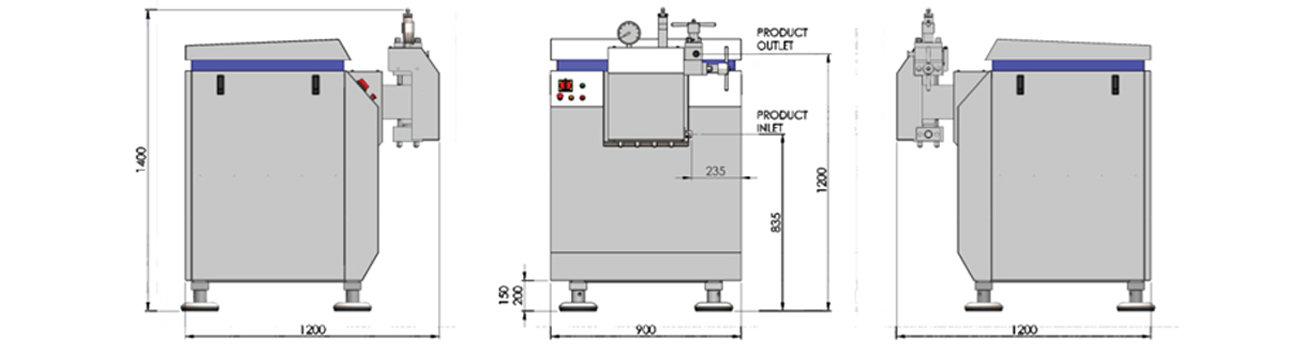

The GSS Homogenizer GS7 available with capacity from 3500 LPH to 1000 Bar with

one stage or double stage depending on application

The GSS Homogenizer GS7 available with capacity from 3500 LPH to 1000 Bar with

one stage or double stage depending on application

Available in a variety of designs & materials, single or two stage, with the standard flat homogenising valve also with a serrated surface or Knife Edge geometry for cell rupture, dispesion applications. The different valve material and designs are available in various option according to application like stellite , Tungsten Carbide, Ceramic etc.

Three piece precision machined block made out of a high tensile, corrosion resistant, stainless steel. Providing easy access for inspection and maintenance. The fully sanitary execution utilises a minimum of parts and seals and is suitable for C.I.P. It comes with many types of pump valves like Ball, poppet, disc type, we always with field replaceable pump valve seats there are many other options available to meet specific productor process requirements comes with many types of pump valves like Ball, poppet, disc type, we always with field replaceable pump valve seats there are many other options available to meet specific productor process requirements.

Homogenization technology uses efficient high pressure energy to break particles present in fluids to the smallest possible size, down to nanometer range. This process creates a stable emulsion or dispersion by forcing the product through a specifically engineered homogenizing valve under high density fluid-dynamic energy conditions thus improving product shelf life and performance.

Number of Plungers : 3

Maxmium Capacity : 3500 LPH

Maxmium Pressure : 1000 bar

Homogenizer Pressure : Manual, Hydraulic, Pneumatic

Increase pressure and capacity can be provide other than mention above, please contact our specialist.

1. ASEPTIC EXECUTION

2. FULL PHARMACEUTICAL VERSION

3. FDA APPROVED GASKETS

4. JACKETED FEED TANK

5. PNEUMATIC PUSHER FOR FEED TANK

Designed according to the international safety rules

Technical Specifications are not mandatory and subject to change without notice.