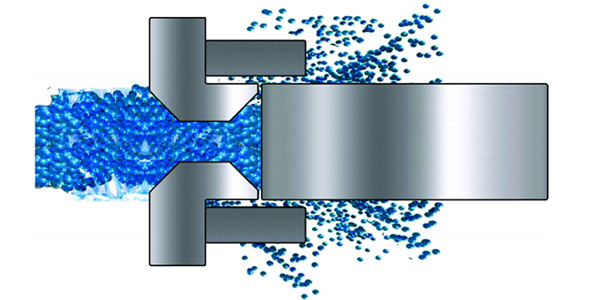

A pressurized product is subjected to turbulent and laminar forces in a very narrow ring-shaped gap. In this process, fat globules or agglomerates are broken up and evenly distributed.

This physical energy input results in stability, color intensity, flavour, consistency and a long shelf life, thereby reducing the use of stabilizers.